Semi-pallets (800 x 600 mm) are becoming more and more common and more and more unstable.

The required pallet height, the columnar tiles, the quality of the Secondary Packaging and Newton's Laws of Motion all line up to make this format a challenge to transport safely.

From VALUEING NEWS we make echo of an expert´s opinion on the matter. Mr. José Antonio Martín Martín is an architect and expert in building structures whose opinion is useful for palletised load stability. After all, a fully loaded pallet must be configured in such a way that the structure is self-supporting and can withstand mechanical stresses while protecting the structure itself and its contents. In this respect it is not very different from the properties required of a building structure.

In today’s case study we consult on the challenge of load stability and load integrity on a pallet of reduced dimensions such as the 800 x 600 mm HALF-PALLET. Supermarket chains use this format for high rotation items which go through a process of crossdocking and are delivered directly into the store such as milk, oil, soft drinks, beer, etc.

Our expert clarifies that the SLENDERNESS of the load of the case study conditions its stability and provides us with the technical reasoning.

“We refer to “slenderness” as the relationship between the height of a vertical part or element and the area of its base (affected by certain geometrical characteristics of the load)”.

In the case of a load stacked on a pallet, the acceleration produced by the truck’s movement, both in the forward and transverse directions, produces a horizontal force whose value is the product of its mass and this acceleration. F=m . a

As the width s in the direction of the horizontal force is proportional to the area of the pallet base, we can define “slenderness in the direction of the horizontal force” as the ratio between the height of the load and the width of the pallet in that direction.

λF= h / s

We are going to determine the maximum horizontal force Fmax that the load-pallet assembly can withstand without losing its stability (without tipping over).

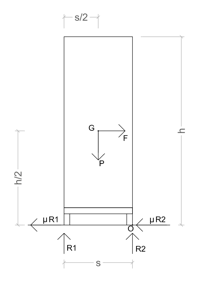

If the load is homogeneous, both its weight P and the horizontal force F produced by walking are applied at the centre of gravity G, which coincides with the geometric centre, located at half its height h/2 and half its width s/2.

At each end of the pallet, the reactions of the support on the ground R1 and R2 occur vertically and, horizontally, the frictional forces whose value is given by the product of these reactions and the coefficient of friction of the ground µ.

The maximum force before overturning occurs at the torsional moment when the end of the pallet opposite the direction of the force loses its support, i.e. its reaction on the ground (R1) becomes zero. As the movement has not yet started, the equilibrium conditions are fulfilled, i. e:

Sum of vertical forces equal to zero:

P – R2 = 0, then P = R2, since R1 is equal to zero.

Sum of horizontal forces equal to zero:

F – µ . R2 = 0; then F = µ . R2, once that µ . R1 = 0

Sum of torsional moments (force times distance) at any point equal to zero.

We choose point O to take torsional moments:

F . h/2 – P . s/2 = 0;

since R1 = 0 and the other forces pass through point O and produce no torsional momentum.

F . h/2 = P . s/2 ;

As we have stated when R1=0, the force will be the maximum admissible force,

Fmax = P . s / h

The expression obtained indicates that the maximum horizontal force that can be applied to our load-pallet assembly, without making it tip over, is directly proportional to the weight and width of the pallet (which are in the numerator of the expression) and inversely proportional to the height (which is in the denominator).

The s/h ratio is precisely the inverse of the «slenderness» that we have defined «in the direction of the force»,

1/λF = s/h, so, Fmax =P/λF

In conclusion, maximum strength is inversely proportional to slenderness. This means that the slimmer our load is, the proportionally less stable it will be. In other words, if we halve the width of the pallet, we must also halve the height of the load so that it behaves in the same way during transport. As this is not feasible in reality, we will have to consider specific tertiary packaging that doubles the load securing and stability and therefore a specific redefinition for this type of format that is completely different to that applied to the full 1,200 x 800 mm pallet.

José Antonio Martín Martín

Architect

Selfless contributor to VALUEING NEWS